Business Overview

Polynet has had more than 20 years of experience in the automotive industry.

We are currently expanding our operation both domestically and internationally into the medical device and consumer product industries.

FROM ADVICE TO TURN-KEY SOLUTIONS

We work to satisfy all of our customer’s needs by providing a One-Stop-Service on each product journey from design, material selection, and mold creation to process optimization, quality check, and market delivery. In addition, we are always on the lookout for ways to improve our processes for better customer satisfaction.

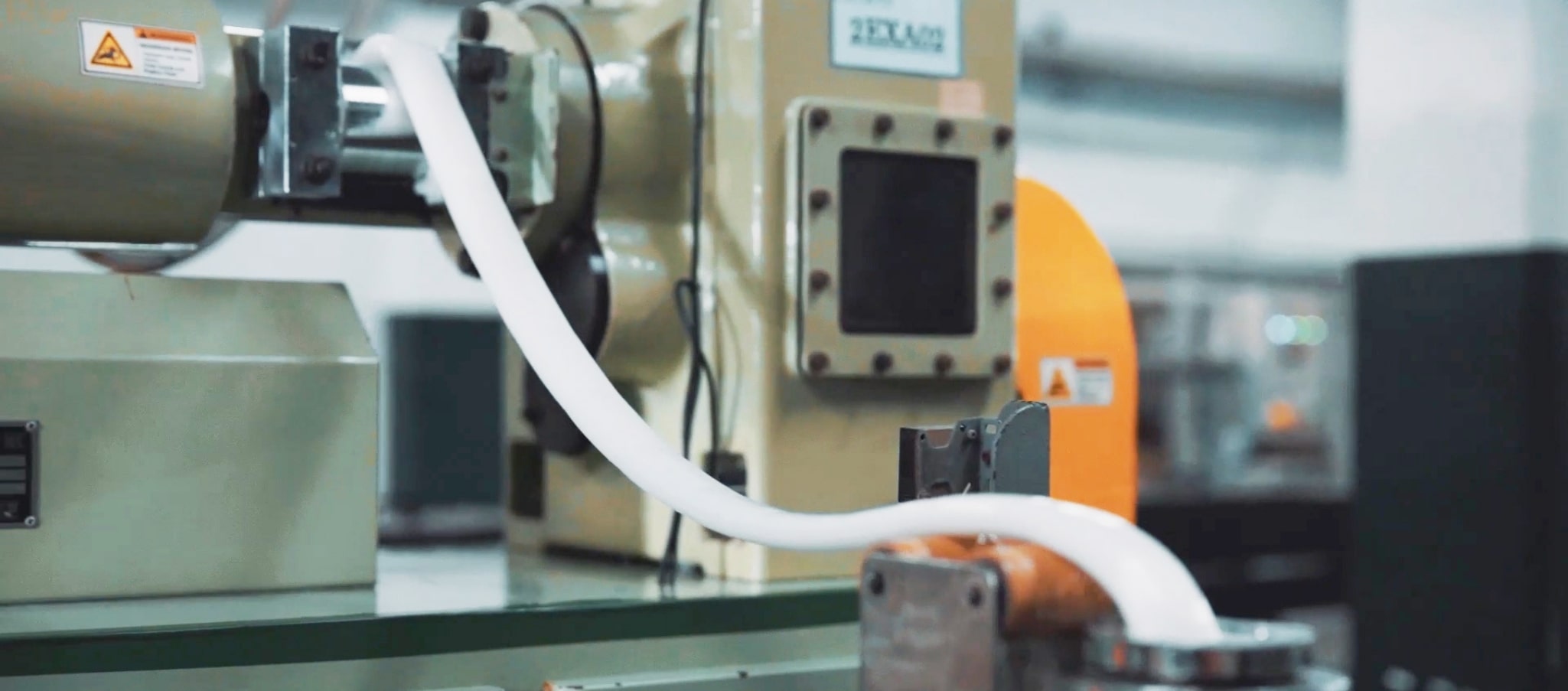

Compounding Process

- Our automatic mixer system ensures the consistency of production that translate to high quality products for our customers.

- All major chemicals used in rubber manufacturing is stored in our specialized tanks underground and fed directly to the fabricating equipment making our factory clean and safe for the workers.

- We have experts in the field who will work side by side with the customers to determine the best possible solution for each product.

Molding Process

- Our machines have the capability to manufacture rubber, plastic, and silicone products using either injection, compression, or extrusion methods.

- Our machines meet all international standards in both Europe and Japan giving our customers the peace of mind that the results will be accurate on time.

Mold-Making Process

- Comprehensive service that comprises process design to optimize product throughput, mold manufacturing along with troubleshooting and adjustment to ensure the final quality of mold.

- High quality machines that meet the industry standards in Japan and USA.

- Specialized experts with 20 years of experience in mold design.

Assembly Process

- We have an array of manufacturing equipment and techniques to serve our customers in multiple industries such as the medical device and automotive fields.

- Our team of experienced engineers guarantee the quality of each and every one of our products.

Research and Development

- We are ready to provide the best experience for our customers with our in-house One-Stop-Service.

- Our R&D team works closely with our partners to innovate new solutions that address our customer’s needs.

- We have specialized equipment that test different properties of products to our customer’s specifications.